From Cables to Connectors: Choosing the Right Interconnect Solution

As with most informative attempts, it is important to begin with definitions. In this case, one first needs to narrow down the focus of the discussion. To “interconnect” is to establish a linking (connect) between (inter) several different things.

Now, for the focus of this article, an electronic interconnect is a piece of hardware that connects a number of different devices by transmitting signals in one or more closed paths in order to perform a desired electrical or electronic function. An interconnect “solution” is the integration of wire, cable, connectors, and other components into a system that efficiently allows all the components of your electrical or electronic device or system to function as intended.

Electronic interconnects can be very small, as in the devices used on a circuit board, or they can be quite large, as used in power distribution systems. For this topic, the cables and connectors that are used to transmit electrical and electronic signals will be discussed. And while the subject may sound somewhat limited, it is wise to remember that many problems in electronic equipment and systems are caused by interconnection failures. How many times have you attempted a quick fix on a device by shaking or hitting it, hoping that the vibration will re-establish a connection? Proof once again that good connections do matter.

Interconnection in the Wireless Age

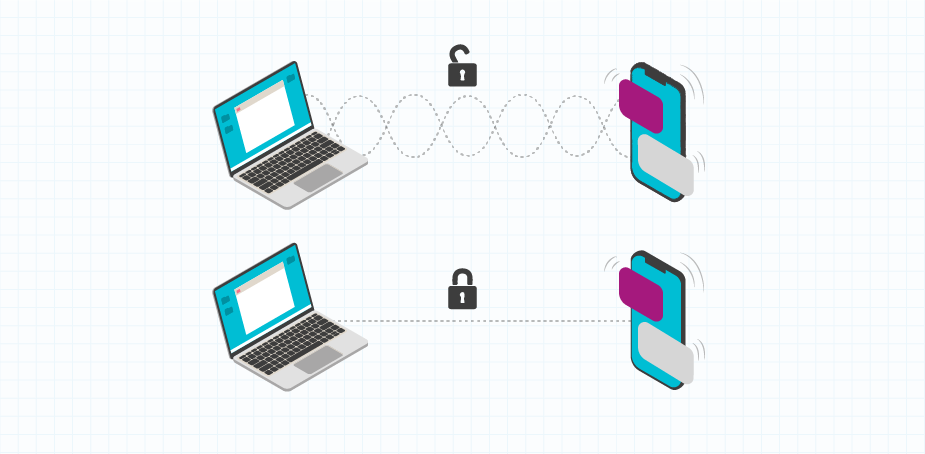

Current interconnect hardware has broad usage, despite the growth in wireless technology for signal transfer. And while wireless sounds new, the technology itself really goes back to the development of radio in the 1800s. The current wireless revolution took off with the growth of IT products throughout the 2000s and the development of mobile broadband, WiFi, and Bluetooth technologies. While many products, both consumer and industrial, feature the benefits of wireless connectivity, there are some noticeable drawbacks that are more than adequately addressed by a wired solution.

Transmitting and receiving signals without hard wiring opens several problems, including security, privacy, network access, signal interference, and bandwidth capacity. Hardwired interconnects either totally avoid or reduce these problems, particularly in places like the factory floor, which can be electronically noisy and rife with other interference, both internal and external in origin. The benefits of a hardwired interconnect solution over a wireless one includes increased security and privacy, along with the ability to deliver both signals (data) and power through a single cable/connector, if needed.

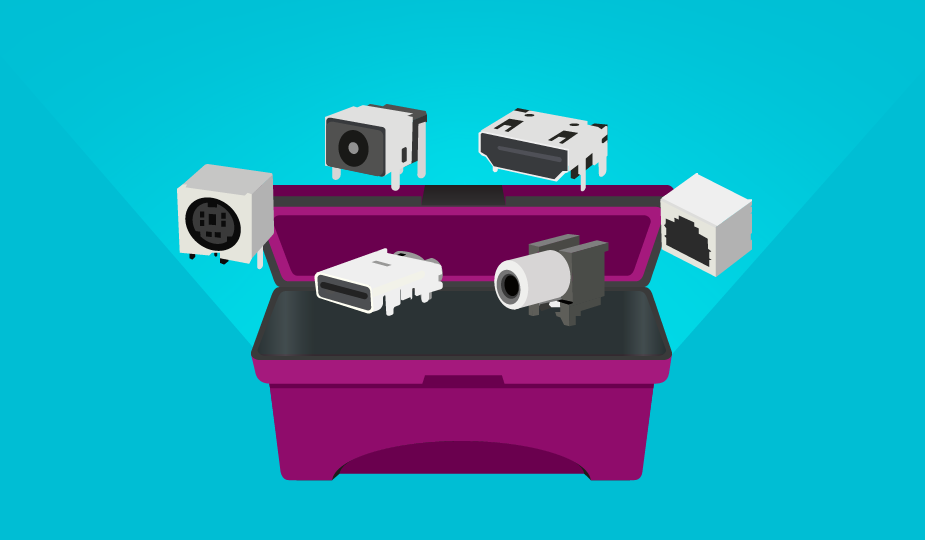

Common Connector Types

Connector and cable interconnect products are available in a broad range of types and styles with features that allow for specific applications, performance, durability, and a range of accessories. It is useful to remember that the term “interconnect” is very broad. Pairing an appropriate connector set with a cable to meet an application essentially results in a custom interconnect. Buying a ready-made cable set with the necessary connectors fulfills the same need. Some of the connectors available to be used in interconnect devices include:

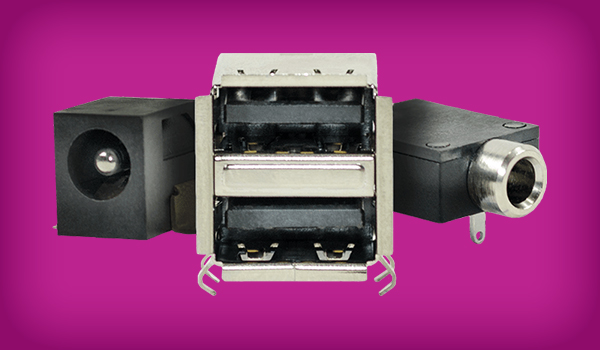

- Audio: Small package size connectors that transfer audio signals, including jacks, plugs, receptacles, and adapters in various mounting styles. Options include shielding and color coding. Learn more in our Understanding Audio Jack Switches and Schematics blog.

- Dc Power: Supply dc power in a range of current ratings. Configurations include jacks, power DIN, plugs, and receptacles. Options include shielding and internal switches with various mounting styles. Learn more in our How to Select a Dc Power Connector blog.

- USB: Used for signal transfer in many consumer and some industrial applications. Numerous configurations following the USB standards, including Type A, Type B, Micro AB, Micro B, Mini AB, Mini B, and Type C. Receptacles and plugs come in various mounting styles and offer ease of use and reliable insertion/removal cycling. Power-only options are also available. Learn more in our various USB blog posts.

- Modular: These are plugs and sockets used with registered jack (RJ) twisted pair cables for data transfer and low speed serial connections. Commonly known as phone plugs or Ethernet connectors, they can easily be field customized and latched in place for security. Learn more in our All You Need to Know About Modular Connectors or The Ultimate Guide to RJ45 Connectors blogs.

- HDMI: High-Definition Multimedia Interface (HDMI) connectors are used for transmitting compressed or uncompressed video and audio signals in entertainment or communications equipment. They come in standard, mini, and micro sizes following the HDMI standard. Learn more in our An Overview of HDMI Connectors blog.

- Terminal Blocks: These consist of modular blocks with insulated frames used to secure multiple wires together for signal or power distribution. They can easily be mounted on a circuit board or a DIN rail. The number of terminals can vary along with the number of levels in each block to save space. Terminal blocks can also be grounded and fused. Learn more in our The Ultimate Guide to Terminal Block Selection blog.

- Circular: These are cylindrical, multi-pin connectors used to transmit data or power. Made of metal or plastic, they are highly reliable and resistant to environmental interference or accidental decoupling. Available in many sizes and configurations. Learn more in our The Basics of Circular Connectors and Cables blog.

- Memory Card: These can include SD, SIM, and smart card connectors used for a variety of portable memory and data storage or card detection applications. They are known for having ultra-compact profiles for PCB mounting and are available in multiple size classes, including standard, micro, nano, and more.

- Pogo Pins: Also known as spring loaded pogo pins, these connectors get their name from the famous pogo stick toy and are utilized in designs where additional connection tolerance is required. As force is applied to the pin, an internal spring compresses allowing for the pin to move inside the outer barrel. This spring-loaded action allows the electrical connection to better maintain contact when faced with mechanical movement and vibration.

- PCB Pins: These connectors are the building blocks of printed circuit board designs allowing for almost endless interconnect system configurations. They are most often press fit or crimped to the PCB and come in a variety of lengths, diameters, and styles.

- RCA: Developed by RCA, these single wire, plug and socket-based connectors are used with coaxial cable and wire mainly in analog audio systems. Also known as phono connectors. Individual cables only carry one signal and can be used to carry both audio and video.

- DIN: These include circular connectors developed under the German national standards organization (DIN) standard. They contain multiple pins in a metal barrel and are keyed to ensure correct insertion in corresponding plugs. Different pin patterns are available. Developed for use in audio and communications equipment.

Connector Features to Consider

As you can see from our list, there are various connector and corresponding cable options for use in interconnect devices. These have been developed over the years to support thousands of different applications ranging from data, audio, and video communications to power distribution. They are found in computer, audio, and security systems in homes; wire harnesses in cars, trucks, and airliners; process control systems on the factory floor; networking installations in offices, hospitals, and laboratories; and many other settings.

Suffice it to say that interconnect devices have been largely customized to each application and are driven by it. In the process, standard interconnect products (connector and cable pairings) have been developed and marketed. As you consider your own application needs, your equipment decision process will likely cover either a standard solution or a custom one.

In the process of this decision, there are several features or factors to consider when choosing an interconnect, which can include the following:

- Size – Your application will largely determine the size of the interconnect you require. Fortunately, interconnects are available in a broad range of sizes. Environmental factors also come into play here. Factory floor applications that require user protection (e.g., gloves) mean that applicable interconnects will need to be sized appropriately.

- User Custom Requirements – Features of an interconnect that allow for more effective usage, like knurled barrels for ease of grip when removing, strain reliefs to prevent cable separation, audible signals when properly seated, etc. Building in these features will allow for a more robust overall product experience.

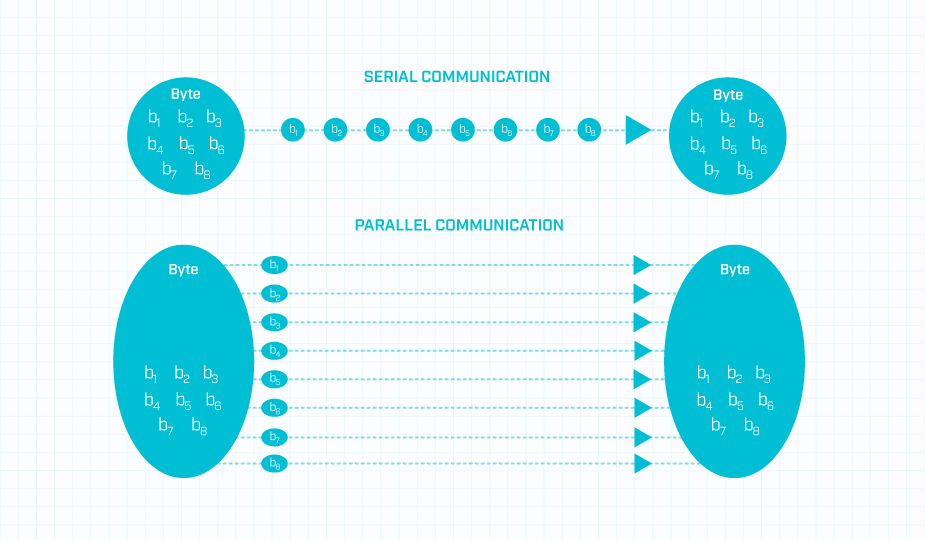

- Data Transfer – How fast do you need to move data in your application? Do you need megabits or gigabits? Connectors and cables operate within defined signal transfer ranges. For example, USB connectors can range from 480 Mbps to 80 Gbps. As you decide on your current application needs for speed, it may be wise to plan for future upgrades. Consideration must also be given to whether your data transfer is serial (one bit at a time, sequentially) or parallel (simultaneous multiple bit transfer). Some interconnection hardware is also able to handle both data and power (USB and HDMI) for device charging purposes.

- Power Rating – This is simply the amount of power that can safely pass through a connection, remembering that power transfer in a wire is subject to resistance, which generates heat. The current rating of a connector is the amount of current (expressed as Amps) that can be passed through a mated terminal. The voltage rating of a connector is the maximum continuous voltage that may be applied to a completed connection. One thing to remember in this regard is that interconnections should not play an active role in a circuit. They are meant to connect or disconnect. Since power at some level is involved, you will also need to determine if a connector can be inserted hot (with power flowing) or if the power needs to be off prior to coupling or uncoupling.

- Compatibility/Backwards Compatibility – Simply the ability of connectors, designed to meet a particular series of engineering standards, to work with similar devices. A simple example is that a two-prong household electrical connector will be compatible with a three-prong grounded outlet, but not vice-versa. Backwards compatibility means the ability of a connector to work with earlier device versions released under the same standard.

- Connection/Removal Frequency – The ability of an interconnect device to withstand multiple insertion/removal cycles before mechanical failure. If your application requires frequent cycling, a more robust version may be necessary.

- Specialty – Interconnects come in a vast array of designs to meet specific applications. Do you require audio connectors, data connectors, video connectors, or ones that allow multiple functions in one connector, such as HDMI? The ability to anticipate feature upgrades in your application can be important here.

- Ubiquity – Do you want your interconnection to be handled by a commonly-sourced cable, or do you want to add perceived value via a custom interconnect solution related to just your product? This does not necessarily require a completely new solution. Many hi-end audio components continue to use RCA cables for interconnect, even though this technology was invented in the 1930s. The perceived benefits by audiophiles are channel isolation along with color coding of the connectors to prevent signal mixing. Back in the day, Apple adopted the USB 1.1 connector standard for its iMAC G3 machines and discontinued the use of multiple serial and parallel ports in the process. This helped differentiate the new machines in the market.

- Environmental Sealing – Are harsh environments (corrosive gasses, heat, vibration, EMI, radiation, weather, etc.) factors in your application. Ruggedized interconnect products are available that are designed to withstand these external factors and can be sourced once you identify those likely to affect your application. Features can include shielding, watertight seals, jackets & boots, heavy duty components, coatings, and grounding components.

Interconnect products can also be rated by the International Electrotechnical Commission (IEC) for Ingress Protection (IP). IP is a classification system that indicates the degree of protection built into a product from solid objects, dust, liquids, and outside contact. The ratings range from IP20 for protection from solid objects, but not water, to IP69K for resistance to steam and high-pressure water. There are intermediate levels for protection from dust, immersion, and other moisture sources. If your application requires protection, you will need to decide on the IP level rating for the connectors you require. - Manufacturability – How easily can an interconnect system be integrated into the manufacturing process for your product? Do the interconnects need to be installed in the factory, are they shipped separately with the product for customer installation, or do they require field customization?

- Field Customization – Many interconnects were purposefully developed to solve problems with field installation of devices, as in the early telephone system. Modular connectors solved this by allowing for simple field assembly of cables. If your application requires significant field assembly, this will determine your interconnect technology selection.

- Reliability – This usually involves connection/removal frequency, or the ability of an interconnect device to withstand multiple insertion/removal cycles before mechanical failure. If your application requires frequent cycling, a more robust version may be necessary. You may also need to consider if the completed product will require frequent movement or complete portability and match interconnect features to deal with this vibration factor.

- Connector/Cable Compatibility – It may go without saying that connectors must be matched with an appropriate cable. This not only applies to matching sizes, but also must consider maximum cable lengths that will function with interconnect standards, like Ethernet. There are also multiple types of connectors and features to consider, including locking connectors, pressure fit, latched, magnetic, shielded or unshielded, co-axial, flat cable, and more. Even when you believe your interconnect requirements have been specified, it may be wise to meet with your component supplier to make sure you have not missed any options.

- Mounting Style – Does the application require freestanding cable interconnects? Or does it require the interconnect to be an integrated component in the system? In the case of the latter, will it be panel mounted, PCB mounted, externally mounted via terminal blocks, etc.?

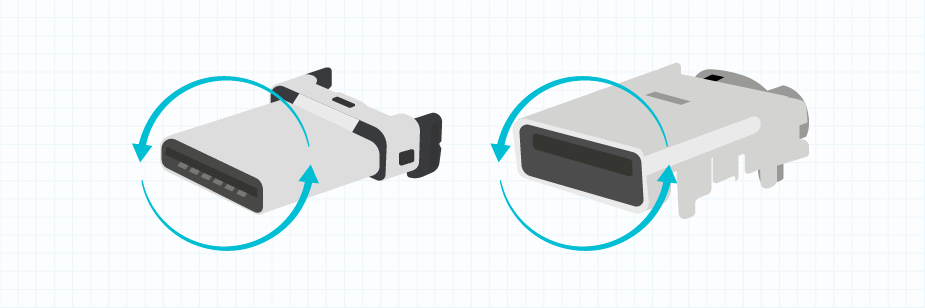

- Orientation – Most connectors can only be installed in one direction or polarity to function properly. Does your application require male/female connectors on opposite ends of the cable to maintain polarity, or the same gender on each end? Will the interconnect need to be rotationally symmetric (connected in a specific direction), or can it maintain functionality if flipped 180 degrees? USB Type A cables can only be installed in one direction as compared to USB Type C which can be flipped and still function correctly.

USB Type C offers the convenience of a reversible mating interface - Expected Product Lifespan – Most products are not purposefully designed with obsolescence in mind, but all products mature, lose functionality due to improvements in technology, or are phased-out by new engineering standards or market demands. An interconnect system is an integral part of most electronic or electrical products or systems. Specifying the right interconnect system can add to a product's expected lifespan by building in capacity for added speed, power handling, etc.

- Safety Standards – Consensus engineering standards applicable to interconnect products are developed by organizations such as UL, IEC, ANSI, NEMA, CSA, and ISO. They exist to improve compatibility, increase efficiency, assure performance, and promote safety in the products they cover. Depending on your particular application, several different standards may cover the devices you are selecting and may influence your product decisions. For more information on this, read our blog on Understanding Connector Safety Requirements.

Summary

The sharing of data or power between devices or systems sounds like a relatively simple task, but there are many options to consider, and this article has only covered the major aspects. The interconnect products you consider and ultimately choose will help to define not only the functionality of your product or system, but also its ease of use, scalability, adaptability to technology change, and ability to meet market demands. Suffice to say, the more your design team can plan upfront, the more closely your interconnects will match your needs today, and in the future. CUI Devices has a range of interconnect solutions in the form of cable assemblies and connectors to help you get there.