All You Need to Know About Modular Connectors

The adage “necessity is the mother of invention” could not be more appropriate than in the development of modern, modular electronic connectors. Their invention, improvement and acceptance has helped fuel the explosion of both voice and data communication worldwide. As usual, a bit of history sets the stage.

Back in the 1930s through the 1960s the phone system was dominated by the telephone companies who owned the hardware and did not allow third-party equipment, even in private homes. Linking buildings and individual phones to the network was accomplished through old, bulky connectors in use since the 1930s and via individual wires that needed to be installed and serviced by a technician, usually meaning a costly “house call”. While the interconnect hardware was robust for the time, the system was ungainly and inefficient.

With the growth of the consumer and business phone system, AT&T began looking for a way to cut service costs and provide a simpler connection system. In the late 1960s AT&T assigned Western Electric the task of developing a solution. Their work led to a “modular” system of standard connection components that were smaller, cheaper to produce, and easier to install than the prior version. This system was first released to the public on AT&T’s popular Trimline phone in 1965, and the individual connectors and cables became accessible to the public in the early 1970s.

Also, in the 1970s, a U.S. Federal Communications Commission (FCC) order established a standard for interconnection between phone company equipment and customer equipment. This standardized the interface and established separate ownership of home or office wiring from that owned by the service provider. These connections used the newly developed modular connectors. In 1976, the FCC mandated a registration system for these connectors, and they became known as Registered Jacks (RJ).

The RJ interface specification includes the physical construction of the connector, the wiring patterns, and the signal specifics. Registered jacks are labeled with the letters RJ, followed by additional digits to indicate the type and minor variations. Modular connectors and RJ connectors are common names for the same devices. Despite the fact that these were standardized over forty years ago, modular connectors continue to grow in usage in many applications due to their wide adoption, availability, and ease of use.

How Do Modular Connectors Work?

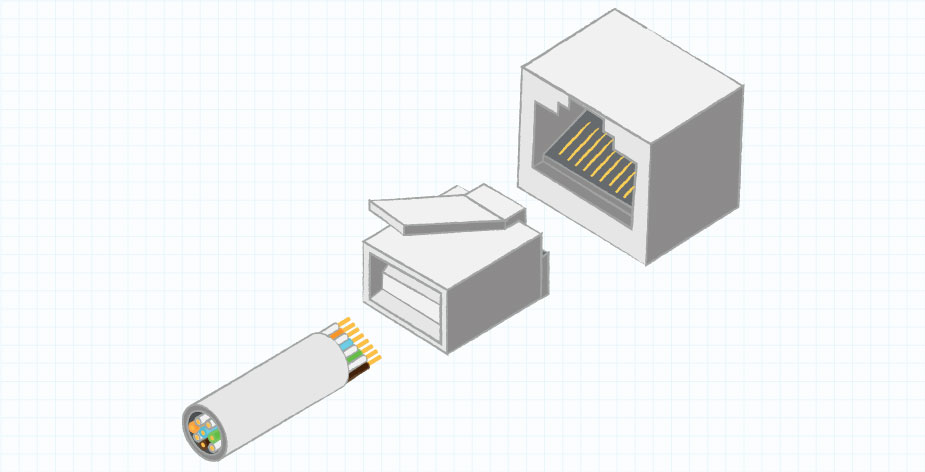

Modular connectors are molded with a simple plastic housing that encases stamped metal contacts separated by insulating channels. The stamped metal in the plug mates with similar material in the jack. A portion of the plastic housing locks the cable or cord in the plug, allowing for strain relief. A latch is included in the housing to securely snap the connector into the handset, phone, wall outlet, or other device, making the device easy to plug and unplug.

The addition of a modular connector or jack to a cable is easily accomplished with a crimping tool, making field service simple. Individual connectors may have an even number from two to ten positions (locations for contacts), depending on use. Due to this, connector body widths vary. Not all of the positions, however, may have contacts installed in them.

Phone connectors (RJ11) usually have four to six connections and Ethernet (RJ45) typically use eight. The naming scheme describes how the connector is wired. For example, a 6P2C connector has six positions and two contacts. A four position, four contact connector, or 4P4C, is the standard connector typically used on the ends of phone handset cords. However, this naming scheme does not define the purpose of the wires. Modular (or RJ) connectors are also classified as male (plugs or headers) and female (jacks or sockets). Some modular connectors can also be used to supply low voltage ac or dc power to a device, like a telephone or other small electronic devices.

Standard Usage and Applications

Proven performance, availability of existing stock, ease of use, and simple design have made modular connectors an easy fit for many applications. The most common uses are in phone systems, data networks, and low-speed serial connections. Their efficient and economical size has also led designers to use them as replacements for bulkier and more expensive connectors in various products. Their extensive use worldwide makes them a critical component in data and voice communications.

Modular Connector Capabilities and Benefits

In addition to their standard usage in voice and data transmission, modular connectors are also widely used in both product manufacturing (OEM) and field installation and repair (MRO) settings. In the OEM area, the benefits of using modular connectors include:

- Low cost

- Off-the-shelf availability

- Solderless assembly of connector and cable

- Easy customization of cables

- Jacks can be surface mounted and reflow soldered for board use

- Ruggedized versions available for industrial applications

In MRO settings, some of the same benefits apply, such as low cost and product availability. Maintenance, repair, and operations issues, however, often center around replacement of old parts, avoidance of production down-time, and increasing system reliability. The additional benefits of modular connectors for MRO issues are:

- Simple upgrade or replacement of old connections

- Easy field assembly with simple tooling

- Ability to customize cable assemblies on site

- Multiple connector and wiring options

- Simple training of field service personnel

In both the OEM and MRO areas, modular connectors offer cost-effective solutions based on the simple, plug-in/unplug nature of the connectors, the reduction in field service calls due to ease of user self-service, and easy customization.

Modular Connector Types

The variety of different, application specific modular connectors has grown significantly with their increased use worldwide. A quick run-down of the most popular types, features and uses would include the following:

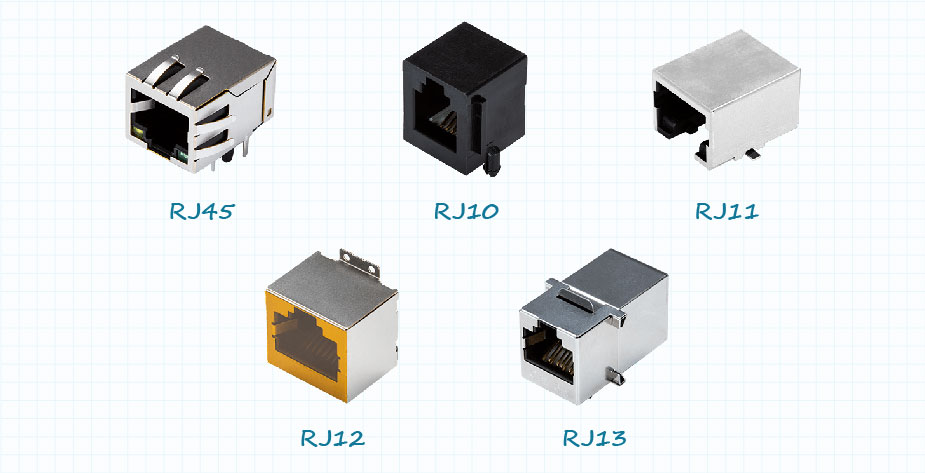

- RJ10 - simple, 4 position, 4 contact, rectangular shaped device used to connect telephone handsets to a receiver.

- RJ11 - 6 position and either 2 or 4 contact, square device used to connect telephone lines and modems.

- RJ12 - identical in size to RJ11 but with 6 positions and 6 contacts for use in larger telephone systems.

- DEC MMP/MMJ - a modified (small form factor) version of the RJ11/12 connector. Modified Modular Plug (MMP) and Modified Modular Jack (MMJ) devices were used in Digital Equipment Corporation (DEC) equipment.

- RJ13 - 6 position, 4 contact device similar to RJ12, but with a behind-the-line circuit.

- RJ14 - 6 position, 4 contact device with two lines used to connect 2 phones or modems.

- RJ21 - modular connector with contacts for up to 50 conductors, used to connect up to 25 circuits, as in a large phone system.

- RJ22 - similar in shape to RJ11, but with 4 positions and 4 contacts, typically used in handset connection.

- RJ25 - 6 position, 6 contact device similar to RJ11 but can connect up to 3 devices.

- RJ45 - 8 position, 8 or 10 contact device used for Ethernet-based local area network (LAN) connections. Read our blog, The Ultimate Guide to RJ45 Connectors for more details.

- RJ48 - 8 position, 8 contact device similar to RJ45 but for connection to shielded cables used in T1 data lines that extend longer distances and may be exposed to the environment.

Modular Connector Features

The broad array of modular connectors available today is highlighted by additional special features available to fit specific applications. Here are some of the available options:

Shielding

For longer cable runs, or for applications on the factory floor which may be subject to EMI or RFI, shielded cabling is often used. Shielded cables incorporate grounding to cancel the effects of EMI/RFI, but the connectors and jacks used in the assembly must also be shielded in order to absorb the interference and channel it to ground. Shielded RJ45 and RJ48 connectors are widely available.

Keying

True RJ45 connectors are keyed with an attached tab that allows insertion into a socket in only one orientation to avoid improper wiring. This is opposed to standard 8P8C connectors that do not have this security feature. Embellishments to this security feature are also available using keying and color coding to allow for restricted access to network connection points.

Mounting

Modular connectors for OEM applications offer most standard component mounting methods, including panel mount, board mount, through hole, and surface mount attachment. Modular jacks (or sockets) can also offer vertical or horizontal orientation.

Display and Indicator Functions

Modern modular connector products can also incorporate LEDs of various colors to indicate connection status.

Hi-Reliability (Hi-Rel) Products

Modular connector products are increasingly finding their way into systems that require high reliability and performance, like military, aerospace, and defense applications. They are also increasingly being used on the factory floor, in automation or machine vision systems. To meet the needs of these systems, robust modular connectors can incorporate EMI/RFI shielding, special keying, protective boots, or robust parts to allow for increased insertion/removal cycles.

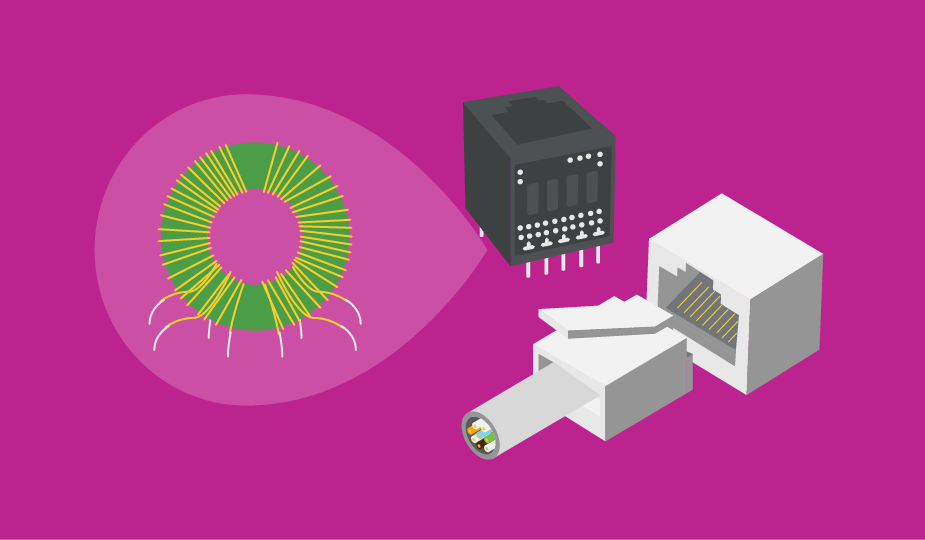

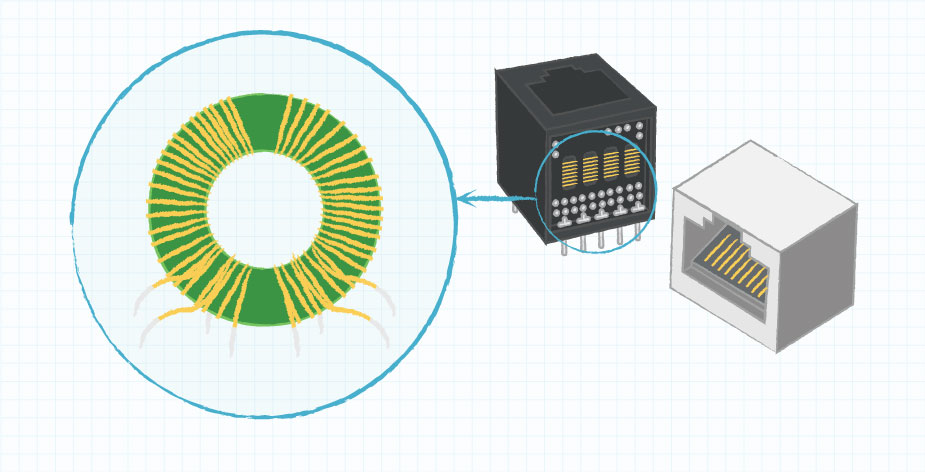

Integrated Magnetics

In any Ethernet interconnect application, magnetics must be considered since they are part of the Ethernet specification for xBASE-T networks. Integrating the magnetics into the RJ45 jack leads to better EMI shielding and more reliable connections. RJ45 modular connectors with integrated magnetics have been available for some time. The magnetics are wire-wound components in the jack that protect against faults and transients, offer electrical isolation, plus signal balancing and impedance matching.

Key Modular Connector Design Considerations

In designing modular connectors into a system, there are several items and performance specifications to be considered and decided upon. These include:

- Pin Outs - the assignment of each of the various contacts within the connector, depending on application and future use.

- Current Rating - the maximum suggested flow of current (expressed as amps) that a device can tolerate.

- Voltage Rating - the maximum operating voltage able to be handled by a device. Both current and voltage ratings are standardized with only rare variations between product offerings.

- Contact Size - also known as termination size, is the maximum diameter wire (AWG) that a connector can accommodate. The higher the AWG, the thinner the wire.

- Number of Contacts - the number of connections available within the device. In modular connectors, this is always an even number.

- Mounting Types - how the socket is integrated into the final product. Can be panel mount, board mount, surface mount, through hole, etc.

Modular Connector Applications and Markets

As has been mentioned, modular connectors are most commonly used in voice and data communication devices, like telephone systems and computers. However, their usage in modern products and systems has expanded due to their ease of design-in, flexibility, and availability. The creation of Power over Ethernet, or PoE, has further expanded their usage. PoE allows the transfer of power through the modular connectors and cables to connected devices, increasing portability, and decreasing infrastructure for many small devices, significantly widening the application list.

Specific applications and markets that are incorporating modular connectors include:

- Networking and Routers

- Office Machines

- Industrial Controls

- Servo Drivers

- Medical Electronics

- Motion Control

- Test Equipment

- Security Systems

- Smart Lighting

- Commercial and Retail Equipment

- IP Cameras

- VOIP

- Set Top Boxes and Gaming Systems

- Development Boards

- Hi-Rel Devices

Summary

The modular connector system was engineered to offer a modern answer to an antiquated and labor-intensive telephone interconnect process. It has succeeded beyond expectations, presenting a simple interconnect solution for many other applications and markets. Offering easy design-in, quick and easy installation, deep breadth of products, and simple user accessibility, it has been accepted worldwide. Designers should work closely with product suppliers to understand the RJ nomenclature and specify interconnect devices that fit both present and anticipated needs.

Using modular connectors to retrofit or update existing products or integrating them into new systems and networks can lead to a very positive outcome.