The Importance of Thermal Interface Materials

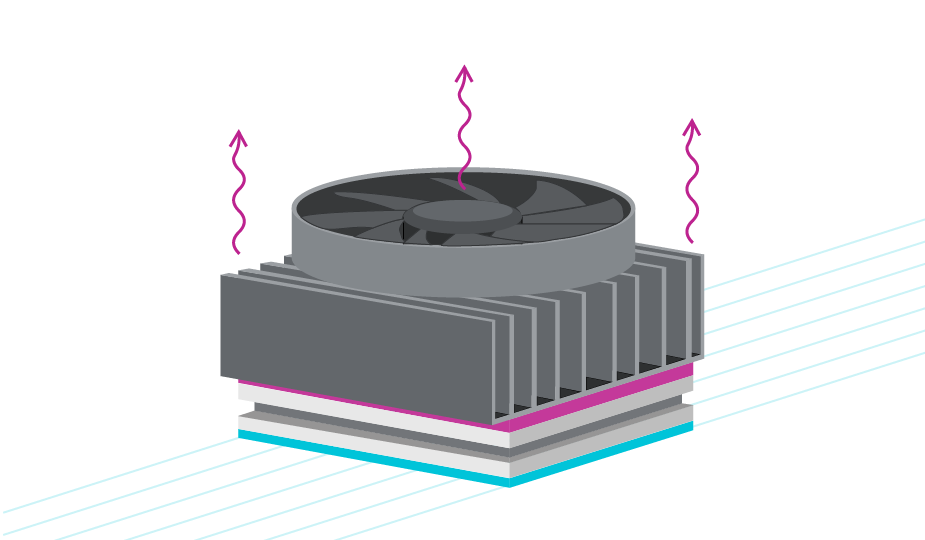

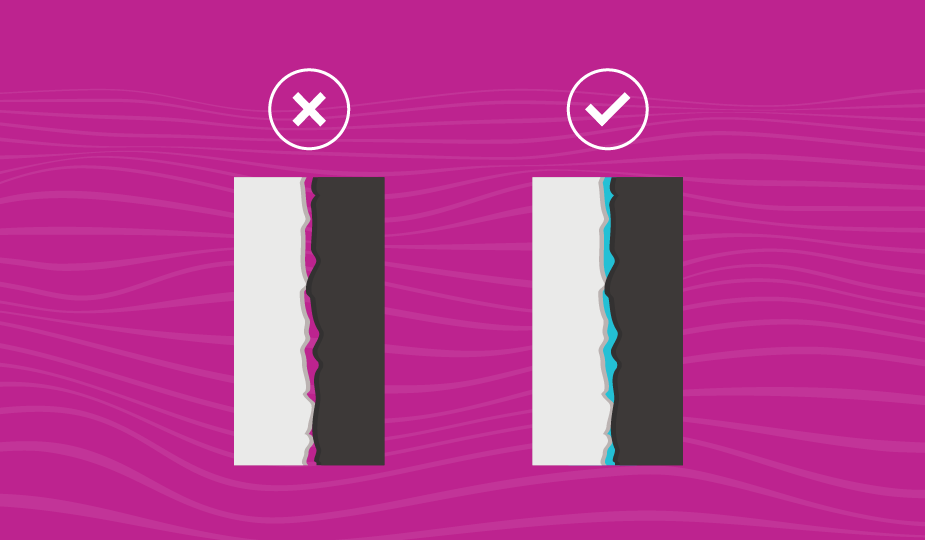

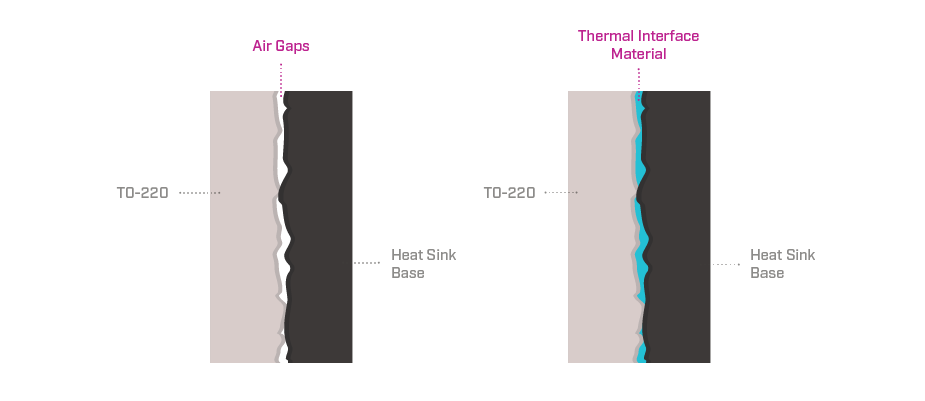

A lot of focus is given to fans, heat sinks, and Peltier devices when discussing thermal management, so it can be easy to overlook the crucial way these pieces are put together. A Thermal Interface Material (TIM) is what makes certain that these other heat management methods perform at their highest efficiency. A TIM is basically any material that reduces the thermal resistance between two surfaces. As the surfaces may not be completely flat or smooth, there can be air gaps and voids between the two surfaces. The purpose of these materials is to fill these microscopic gaps with a substance that has better thermal conductivity than air. TIMs can be one of many different materials used to improve the thermal conductivity in order to achieve the most efficient heat transfer from a heat-producing component, such as a power transistor, to a heat dissipator, usually a heat sink, thermoelectric cooler, or combination thereof.

What is Thermal Conductivity?

To understand exactly how filling these microscopic gaps can help with heat transfer, it is important to understand thermal conductivity. As the term suggests, the thermal conductivity of a material is its ability to transfer heat and does not depend on the size of a specific part. This is typically measured in a unit of power divided by area times temperature, such as W/m°C or W/m*K. Note that 1 unit on the Kelvin scale is equivalent to 1°C, so when doing calculations, the only concern is the relative change in temperature, not the absolute value.

When dealing with heat dissipation, the higher the thermal conductivity, the better. Heat transfer in low thermal conductivity materials has a low transfer rate, whereas materials with high thermal conductivity have a high transfer rate. To put things into perspective, the thermal conductivity of air is just 0.0263 W/m*K, or about two orders of magnitude less than that of thermal interface materials. If there are air gaps between the package and the heat sink, heat dissipation will be hampered. The TIM, which has a much higher thermal conductivity than air, fills these gaps and, as such, facilitates better heat transfer.

What is Thermal Resistance?

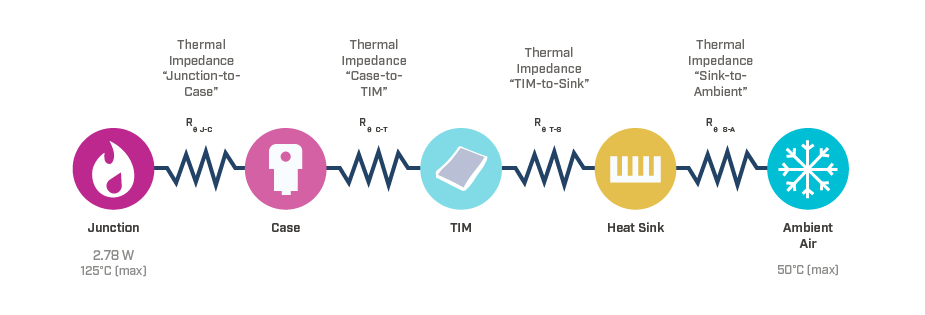

Conversely, thermal impedance or resistance is dependent on the shape of a specific part and has units of temperature divided by power, degrees Celsius per Watt, which is a more helpful unit for design purposes. Thermal resistance is covered in-depth in our Overview of Thermal Management and How to Select a Heat Sink blogs, but will be reviewed quickly here. With the unit, C/W, thermal resistance calculates how many degrees warmer, in Celsius, a junction will get, per watt of power dissipated. Thus, a junction that is transferring 3 watts of power through a resistance measured at 20 C/W will increase 60 degrees Celsius in temperature compared to the ambient temperature. Often, the value for thermal resistance is quoted for a specific area with a certain medium, for example, a TO-220 package to air without a heat sink.

In the case of devices that are integrated with other devices, a new thermal resistance is given. However, this thermal resistance is given with the assumption that a perfect connection between the two surfaces exists, which is not the case. It is in these situations that the thermal interface material is used to create as close-to-ideal conditions as possible. While this does help, it does add a level of complexity because the thermal resistance of the TIM then needs to be included in the calculations. It may be considered ironic that the thermal interface material, while dropping the thermal resistance between two objects, has its own thermal resistance. While this amount is non-negligible, it reduces the thermal resistance between any two objects significantly more than it contributes. Depending on the type of TIM used, this thermal resistance may be given or may need to be calculated depending on the thickness of the TIM and the surface area over which it is used.

What Are the Different Types of Thermal Interface Material?

Thermal interface materials come in many forms, from gels, greases, and pastes to thermal interface pads. Generally speaking, thermal interface pastes, including gels and greases, offer excellent thermal conductivity, high-flexibility, and better fill larger gaps. But it can be challenging to apply depending on the surface area and does not yield consistent results. Applying too much paste, for example, can reduce the overall effectiveness. Conversely, if you apply an insufficient amount of paste, the effectiveness of the thermal interface may be compromised. Also, metal-based pastes, which offer superior thermal conductivity, may result in electrical damage if it squeezes out or accidentally spills onto the PCB. Ceramic or carbon-based pastes are ‘safer’ to use in that respect but not as thermally efficient as the metal-based alternatives.

On the other hand, thermal pads are solid TIMs made from non-silicone or silicone elastomers - though many other materials are available. As an example, CUI Devices’ thermal pads are naturally tacky, electrically isolated, and carry various thermal conductivity ratings from 1.0 to 6.0 W/m*K. One of the main advantages of using thermal interface pads over pastes is that they are much easier to apply. CUI Devices offers them pre-cut to match the profile of our Peltier devices, which adds further convenience and a time-saving aspect during assembly - rather than buying the pad material in large sheets and cutting it down to size. These pads offer greater consistency, less mess, and are more reusable than a thermal paste.

Paste, however, remains popular in non-standardized applications, where users are dealing with a wide variety of different devices, and it would be difficult to stock all the different size thermal pads needed. Thermal paste is also very popular with hobbyists as it is easier to buy a small, inexpensive tube that can be used on a variety of small projects instead of taking the time to get the correct size, hoping that measurements are correct. Here is a quick table summarizing and comparing the various thermal interface material options:

| Thermal Pads | Pastes/Greases | Thermal Adhesives | Phase Change Materials | |

|---|---|---|---|---|

| Description | Shaped pad for specific application sizes. | Liquid of varying viscosity. | Similar to paste but with adhesive properties. | Hard at room temperature but soften at higher temperatures. |

| Price (generally) | Moderate | Inexpensive | Inexpensive | More Expensive |

| Application Consistency | High | Moderate | Moderate | Low |

| Adhesive | Yes | No | Yes | No |

| Electrically Conductive | No | Sometimes | No | No |

| Advantages | Easy to apply, consistent results, when working with the same devices. | Flexible usage scenarios. | Flexible usage scenarios, reduced need for mechanical support. | Easy to work with at room temperature, flows nicely when warmer to fill gaps. |

| Disadvantages | More difficult to use for one-off applications. | Messy, potential short circuits. | Messy and sticky. | Expensive and more messy than thermal pads. |

Summary

Effective thermal management is a multifaceted challenge with many different approaches and solutions. The importance of thermal interface materials as a part of the overall whole should not be ignored. Whether prototyping, moving toward production, or simply using thermal interface materials for hobbyist use, having a good knowledge of why they are needed and how they work can make a night and day difference in the thermal performance of a device.