Push Button Switches 101

Mechanical switches can be reliant on a variety of different potential actuation methods, depending on the purpose they serve. Push button switches, also referred to as pushbutton switches, push switches, or simply push buttons, are prevalent in a multitude of modern applications. This short blog will give an overview of push button switches including their basic operation, common types, and key design specifications.

What is a Push Button Switch?

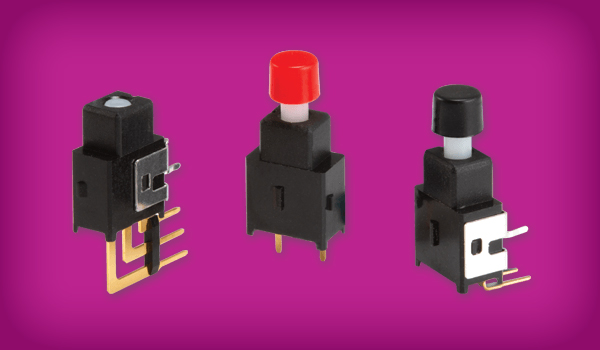

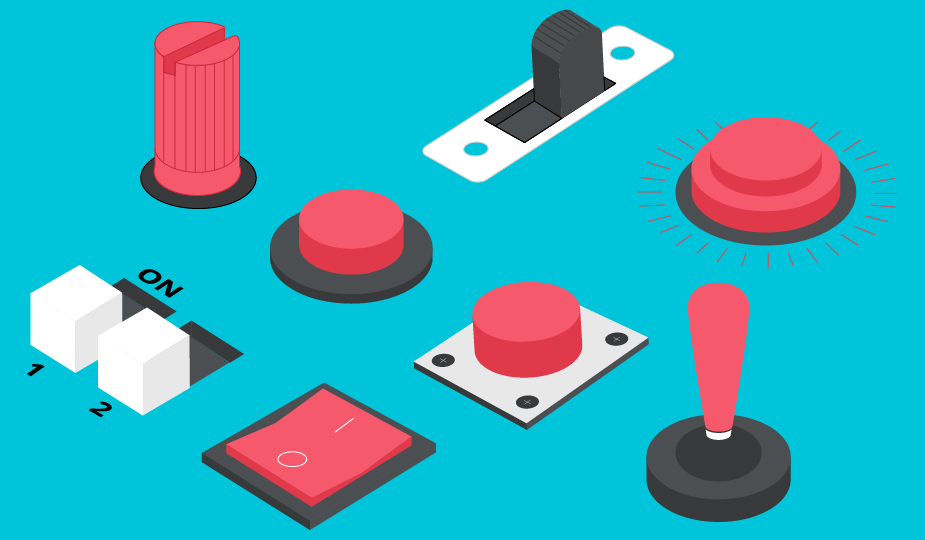

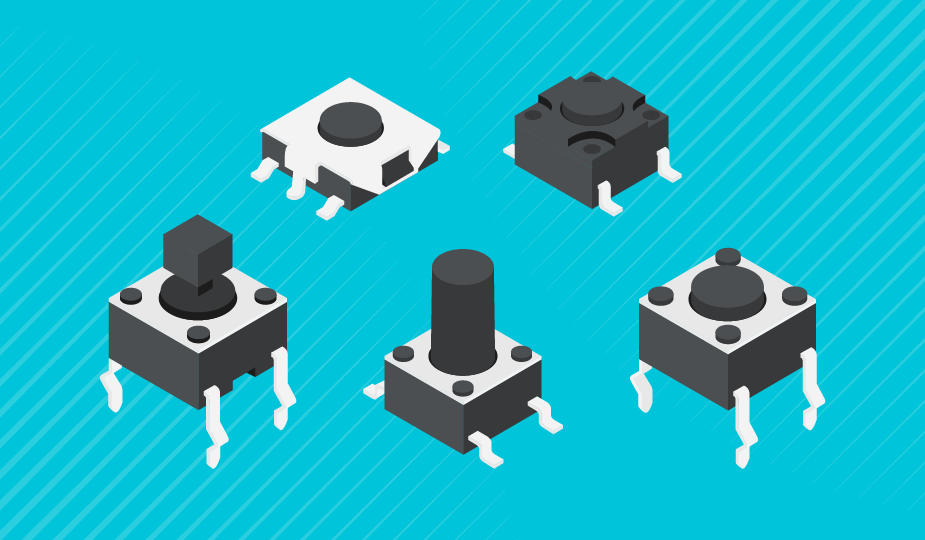

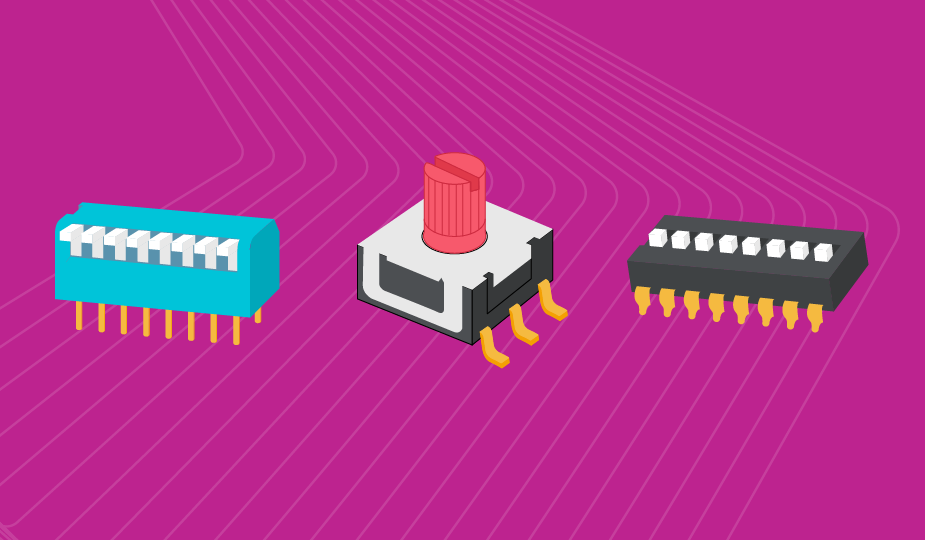

A push button switch is a mechanical device used to control an electrical circuit in which the operator manually presses a button to actuate an internal switching mechanism. They come in a variety of shapes, sizes, and configurations, depending on the design requirements.

How Does a Push Button Switch Operate?

Push button switches rely on a simple in-out actuation mechanism. They can be employed to break (off) or initiate (on) a circuit. Alternatively, they can provide an input for the user interface of a piece of equipment or start/stop a particular function.

Push button switches may be categorized as being either momentary (where the switch function only continues for as long as the operator is pushing the button) or maintained (where the switch function stays latched in that status after it has been actuated).

Types of Push Button Switches

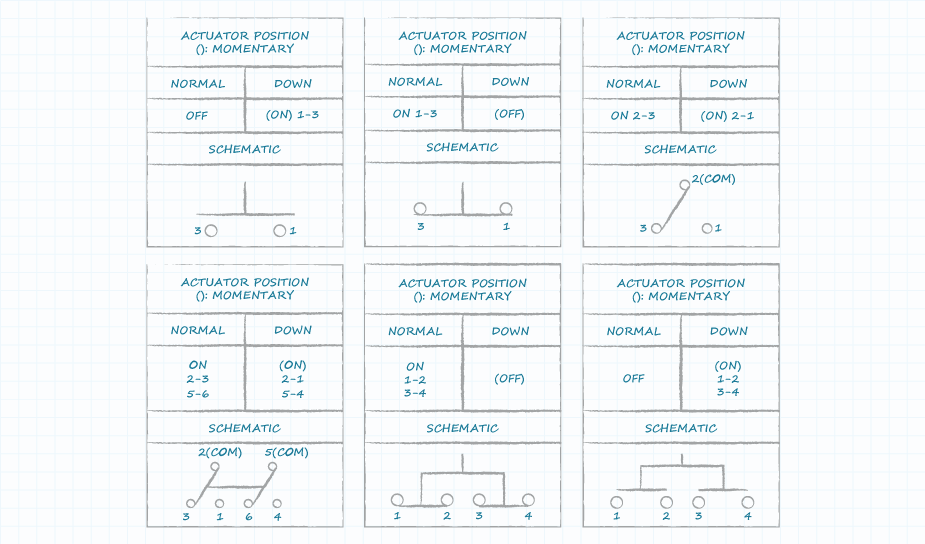

Push button switches can be classified as being normally open (NO) or normally closed (NC). Normally open (“OFF” position) switches complete the circuit when actuated, while normally closed (“ON” position) switches break the circuit when actuated. Within this classification, the functionality of push button switches can further be defined in terms of the switching circuit they utilize.

These are commonly single pole, single throw (SPST), single pole, double throw (SPDT), double pole, single throw (DPST), or double pole, double throw (DPDT). An SPST has just two terminals, so it can only open and close a single circuit. For example, it might be used to turn a motor on and off. An SPDT has three terminals and can thus control two different circuits. Therefore, it may be used to flip between the powering of two separate LEDs or for moving an item of equipment from a sleep mode to an active state. DPST and DPDT switch arrangements allow for the simultaneous control of two isolated circuits. For instance, where one is high voltage and the other is low voltage.

Key Push Button Switch Specifications

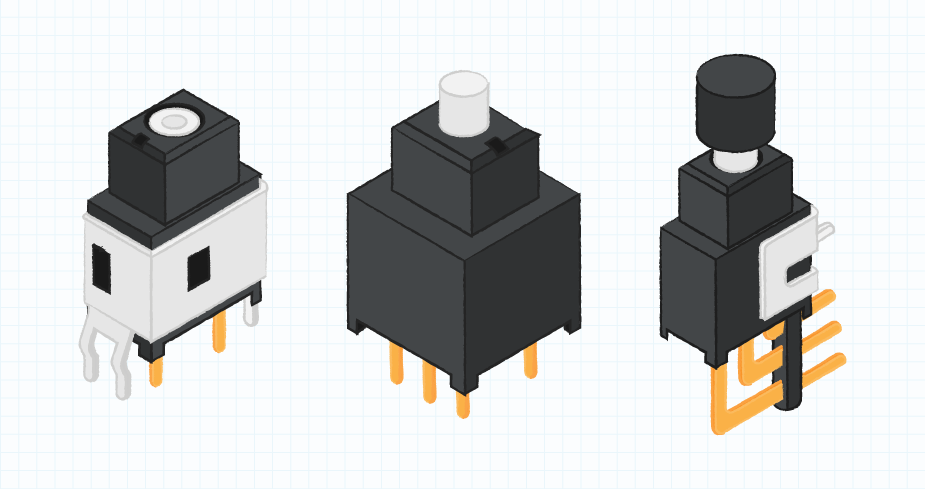

Consulting datasheets will allow for information on specific push button switch models to be compared with one another. The current and voltage ratings of switches are particularly important to ensure they are compatible with a design’s performance criteria. When it comes to mounting style, push button switches are typically found in either surface mount, through hole, or panel mount options. Here is a quick look at some other key specifications to consider:

| Specification | Typical Offering | Description |

|---|---|---|

| Termination Style | Gull wing, PC pin, wire lead, screw terminal, and more | Allow for different mounting options |

| Voltage Rating | Up to 24 Vdc | Maximum voltage across the device |

| Current Rating | Up to 14 mA | Maximum current through the device |

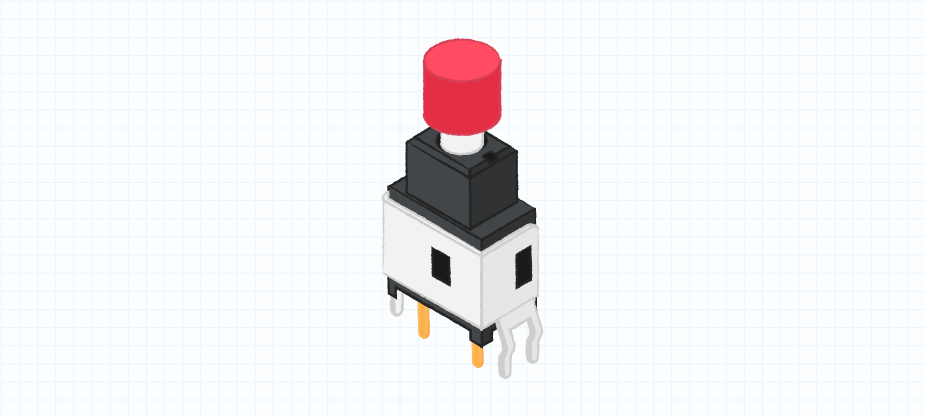

| Actuator Height | Flush, 3.3 mm, 5.4 mm, and beyond | See examples below. Flush push button actuator heights might be utilized in designs where vertical space is limited or where accidental actuation needs to be avoided |

| Pitch | 2.54 mm or 5.08 mm | The center-to-center distance between pins |

| Actuator Cap | Variety of color options/finishes | Selection usually comes down to application needs or user preference. No cap is also an option |

| IP Rating | Rated or non-rated | Push button switches can resist moisture and dust ingress |

For maintained push button switches, an LED indicator may be worth incorporating. This will allow the user to quickly determine whether the switch is actuated at that time or not. However, this feature is unnecessary for momentary switches.

The materials used in the switches can also be enhanced to upgrade their robustness, but this will also raise the associated unit costs. It will therefore depend on the nature of the application to determine what is required.

Push Button Applications and Considerations

Push button switches have been around for quite some time and might be most well-recognized for their use in classic arcade machines. However, their use is widespread in various applications, such as vending machines, portable equipment, household appliances, power tools, and countless other consumer electronics and industrial controls. When looking to source a push button switch, some basic questions to ask are:

- How much board real estate is available?

- What profile height can be accepted?

- Do I need a momentary or maintained contact switch?

- What will be the long-term effects that the operating environment will have on the switch function?

Conclusion

Push button switches are one of the most common types of switches that users and consumers interact with on a daily basis. While a relatively straightforward switch component, push button switches still offer a range of sizes, specifications, and features that need to be understood and considered based on the final application. CUI Devices offers a range of mini push button switches with compact packages, multiple switch functions, and several circuit types.