All You Need to Know About Potentiometers

What Are Potentiometers?

Potentiometers, or “Pots” as they are commonly known among engineers, are essentially resistors that incorporate a mechanical adjustment mechanism enabling their resistance to be changed manually. Resistors, as we know, offer a fixed resistance value and block or “resist” the flow of electrical current in a circuit. A potentiometer is fundamentally a variable resistor.

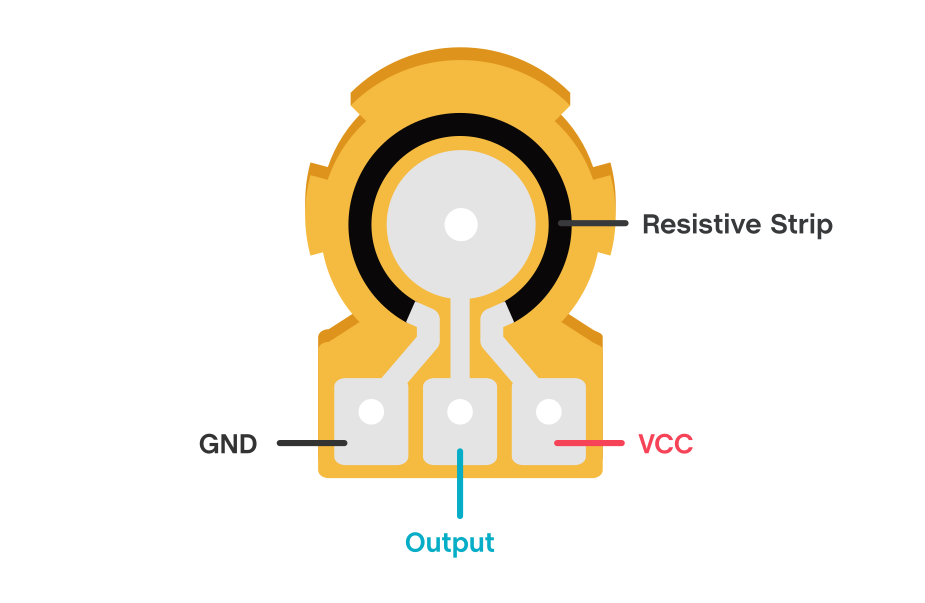

Potentiometers function as voltage dividers that can be used to both adjust voltage output to a circuit, and accurately measure (or meter) electric potential – hence the name potentiometer. They produce a continuously variable voltage output signal proportional to the physical position of the wiper on the resistive element. They are passive components, meaning that they do not need a power supply or additional circuits to function.

A Brief History of Potentiometers

With the explosion in research on and development of electricity in the early 1800s, the thought of a component that could be used to control the amount of electricity going into a device or circuit was explored by many people, but the concept of the potentiometer was not proposed until 1841. It would take until 1872 for the first working carbon potentiometer to be invented by Thomas Edison.

The potentiometers available today are significantly smaller and more accurate than earlier devices and come in a large variety of types and packages, depending on application. They are commonly used in devices and systems to control values, including light levels, audio volume and audio signals, and video brightness and color. They can also function as position sensors.

How Do Potentiometers Work?

Resistance of an object is reliant on several factors. With all else being held constant, the resistance of an object is directly proportional to its length. In other words, an object of the same material and the same size cross-section that is 10 centimeters long will be half the resistance of another object that is 20 centimeters long. Potentiometers use this principle. The adjustable output of a potentiometer is accomplished by varying the linear or rotary position of a sliding contact across a uniform resistance element, lengthening or shortening the path that current flows through. Input voltage is applied across the entire length of the resistive element, and the output voltage is applied as the drop between the fixed resistive element and the sliding or rotating contact. The position of the movable contact across the resistive element determines the amount of input voltage that will be applied to the circuit.

Potentiometers are very rarely used to control more than a watt, since the device must dissipate the input power and would produce unacceptable heat. They instead work by adjusting analog signals used by other components to control power. For example, a simple light dimmer uses a potentiometer to control a TRIAC which varies the light brightness.

Available Types of Potentiometers

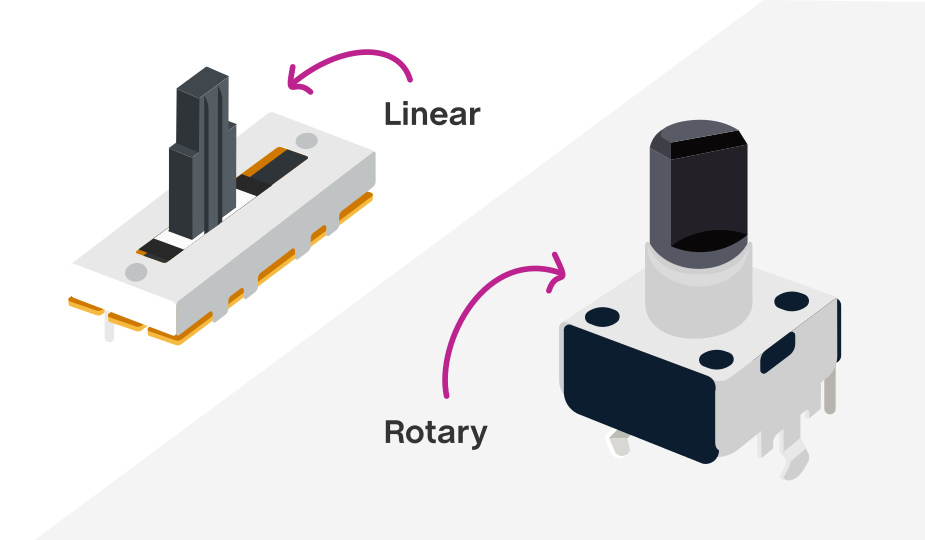

Potentiometers are available in two main forms: analog and digital. A traditional analog potentiometer uses mechanical elements that can be manipulated manually to control the output. Analog potentiometers are available in linear and rotary formats:

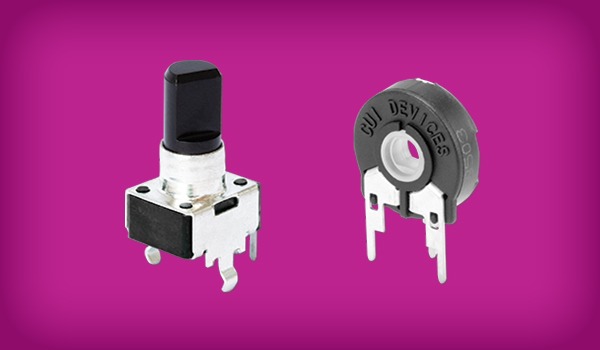

Rotary potentiometers use angular movement from a rotating knob and shaft connected to a wiper element which slides across the resistive element. Turning the shaft varies the resistance and the output. Potentiometers can also be shaftless with an external tool like a screwdriver typically taking the place of the shaft to move the wiper. These are most commonly called trimmer potentiometers or trimmers.

Linear potentiometers use linear (or straight line) motion via a slide to contact the resistive element and vary the resistance and output.

Digital or electronic potentiometers are controlled by digital signals to vary the output instead of by mechanical movement. In this article we are focusing on analog potentiometers.

Additional Potentiometer Sub-Types

There are various sub-types of analog potentiometers, both linear and rotary, that can be specified for an application. These include:

- Presets & Trimmers: these are small, usually board-mounted devices adjusted with a small screwdriver and used for tuning and calibration in a circuit. Presets have specific values and trimmers offer high resolution via multi-turn screws. These are mainly used during calibration of the system and remain at a fixed position most of the time.

- Dual Gang: these are two potentiometers combined on the same shaft that enable the parallel setting of two channels.

- Servo Pot: this is a potentiometer attached to a rotating shaft (motor) that can sense position by measuring the pulse that is applied to turn the motor until the potentiometer indicates that the position corresponds to the incoming pulse. Often used in robotics or applications where precision movement control is necessary.

- Logarithmic: these change resistance logarithmically as the potentiometer is adjusted, closely tracking the logarithmic sound response of the human ear. Used as volume controls in audio equipment.

- Concentric: two rotary potentiometers stacked together with their shafts on the same axis allowing for volume and tone controls through a single mounting hole.

- Thumbwheel: these use a rotary wheel with a tactile edge to allow for fingertip adjustment of the device. Typically used for volume and brightness controls.

- Slide & Dual Slide: use a resistive element and a sliding contact to adjust resistance via linear motion. This offers a linear relationship between slider position and the output resistance, which means this type can also be used as resistive position sensors (linear displacement sensors). Dual slide potentiometers feature a single slider that controls two potentiometers in parallel. Slide pots are often used in studio mixers, faders, or graphic equalizers.

- Motorized Slide: employ a slide potentiometer with a timing belt driven by a small dc motor and timing pulley to allow for automatic remote control. Commonly used in industrial automation and process control applications.

- Single & Multi-turn: single turn pots offer a single rotation of approximately ¾ of a full turn of the control knob to provide adequate control resolution for the application. Multi-turn pots offer multiple rotations of the control knob for increased precision where high resolution is required.

What’s the Difference Between Potentiometers and Rheostats?

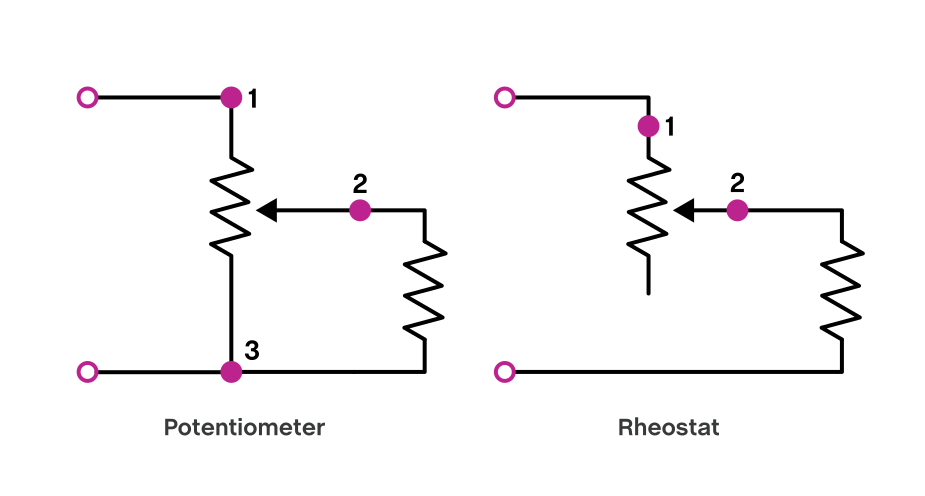

The most basic explanation of the difference between these two devices is that a potentiometer is a three terminal device used for voltage control. A rheostat is a two terminal device used for current control. However, by simply leaving one leg of a potentiometer unconnected, it is possible to use potentiometers as rheostats.

Rheostats are generally high wattage, wire-wound variable resistors used in high current applications to control current flow to devices such as lamps and motors. They contain coils of heavy-duty wire that change resistance in incremental steps by changing the position of the slide element on the resistive element. Rheostats are specified not by their resistive value but by their ability to handle large power levels.

Are Potentiometers and Rotary Encoders the Same?

A rotary encoder is an electro-mechanical device that converts angular position or motion of a shaft into a digital signal. Both potentiometers and rotary encoders sense the rotation of a shaft, but they operate using different principals, offer different levels of complexity, and require different set-ups.

Potentiometers are basically analog devices, although digital variations exist. Rotary encoders are digital devices that use binary logic to indicate position, so a separate circuit is needed to translate their output into a usable signal.

Potentiometers offer easier set-up than rotary encoders, allow for infinitely variable inputs, can divide voltage in a non-linear fashion, and can easily control other analog devices. Rotary encoders, on the other hand, can rotate continuously, have a digital signal, and offer excellent resolution, and while they tend to be more expensive than potentiometers, their precision in motor control makes them ideal in their own way for industrial, automation, and robotics.

A Word About Potentiometer Taper

Potentiometer taper is how the resistance varies as the device armature rotates or its wiper slides on the resistive element. In some potentiometer designs, this is a linear relationship, meaning that when the armature or slide is at its mid-position, the variable resistance is half of the full-scale resistance of the potentiometer.

Other designs offer a non-linear, logarithmic taper (also called audio taper) which more closely mimics the logarithmic sound response of the human ear. This gives the impression of a more balanced volume adjustment across the full rotation or slide of an audio volume control. Inverse logarithmic potentiometers are also available, which offer a reversed operating design. These are used, for example, in audio controls that function in a counterclockwise fashion.

Potentiometer Resistance Ratings

Potentiometers are typically rated and specified by their overall resistance value. This resistance value relates to the entire resistance element, from one terminal to the other. Therefore, a potentiometer rated at 1 kΩ (kilohms) has a resistance across its track equal to a 1 kΩ fixed resistor.

Other parameters to be considered when sourcing a potentiometer include the following:

- Rated Power: the maximum power that the device can handle without damage.

- Resolution: the accuracy of the potentiometer, expressed as a percentage of total resistance and changing resistance caused by each incremental movement of the contact on the resistive element.

- Sliding Noise: amount of electronic noise produced by the movement of internal contact parts.

- Temperature Coefficient: how the observed resistance may change as a function of the operating temperature of the device.

- Mechanical Life: how long the device will perform to specification, usually expressed as number of cycles.

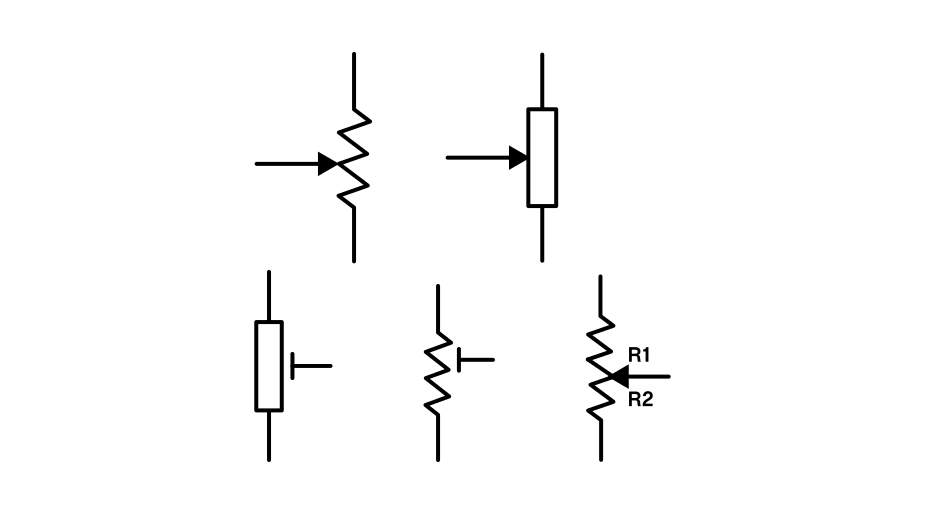

Applicable Symbols and Markings

Potentiometer symbols in a circuit design can differ. The ANSI (American) standard is two straight lines with zigzag lines in between. The IEC (European) standard is a rectangle between two straight lines.

Individual devices are usually marked on the device with an exact resistance value, as in 1K for a 100 kΩ potentiometer. They may also be marked with a three-digit code, the first two digits representing the value of the device and the last digit representing the multiplier. Potentiometers made in the USA and Asia are usually marked with an “A” for logarithmic taper, a “B” for linear taper, or a “C” for reverse logarithmic taper.

Pros and Cons of Potentiometers

As with any electronic device, there are advantages and disadvantages to using potentiometers in an application which must be weighed before final specification. The advantages of potentiometers include simple design, low cost, wide resistance range available, easy and efficient operation, and proven technology. Some of their disadvantages include limited bandwidth, limited current handling capability, mechanical operation subject to wear and contamination, and potential electrical noise generation.

Some Questions to Ask Before Specification

Fundamental questions that will need to be answered include these:

- What are my required device specifications (resistance value, resistance range, power capacity, etc.)?

- Does my design require rotary or slide functionality?

- Do I require a linear or logarithmic taper?

- How long does the device need to function to spec?

- Will the device be used in harsh environments?

- What footprint is required?

- How will the device be mounted?

Common Applications

As noted previously, potentiometers are commonly used to control values in audio and video devices or systems, including volume, brightness, contrast, and color. They can also be used to measure voltage in test equipment and for position sensing in process control and automation systems. Their flexibility and even the opportunity to use potentiometers as rheostats has allowed potentiometers to branch out of these more common applications to integrate themselves into nearly every analog and many digital applications. Whenever there is an opportunity to actively control a circuit or receive feedback from a circuit, a potentiometer can be considered.

Summary

Potentiometers are relatively simple devices that use proven technology to provide the necessary function of voltage control or measurement in many types of electronic or electrical devices or systems. They can also provide precise sensing and measurement of linear or rotary movement. Their availability in a wide range of packages, ratings, sizes, and designs ensures that they can be matched to a vast array of different applications. CUI Devices offers a range of potentiometers in rotary or trimmer options with a wide range of resistance ratings.