PDM vs. I²S: Comparing Digital Interfaces in MEMS Microphones

While microphones in embedded systems have been around for many decades, the usage of MEMS microphones has expanded quickly since their introduction. That growth is compounded by the explosion of voice-based applications in the consumer space - at home, in the car, and as a wearable. Besides their significantly reduced footprint, lower power requirements, and greater electrical noise rejection, one of the main benefits of MEMS microphones is an increase in output options, giving greater flexibility to designers and engineers. Although analog options are still available, two popular output options are the digital protocols of pulse density modulation (PDM) and inter-IC sound interface (I2S).

These interfaces each possess their own distinct characteristics, and both have advantages and drawbacks that engineers need to understand for proper design implementation. As with all engineering decisions, choosing between these two protocols will require a designer to examine the technologies and understand which protocol works better under the conditions of each application. The key considerations that will need to be taken into account when comparing the two technologies are the following:

- Audio quality levels

- Power consumption levels

- Bill-of-materials costs

- The space constraints the design must adhere to

- The operational environment in which the hardware will be deployed

Pulse Density Modulation (PDM)

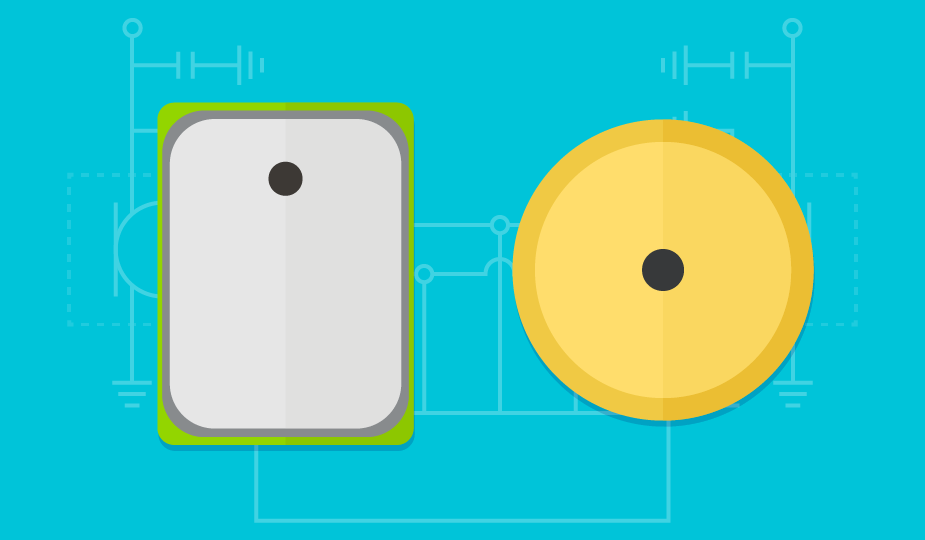

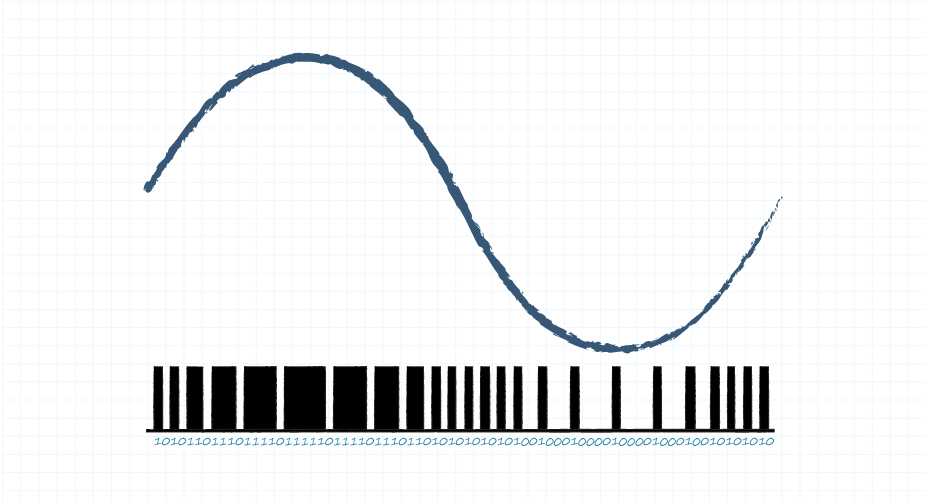

PDM is used to convert an analog signal voltage into a single-bit pulse density modulated digital stream. PDM signals look more akin to a longitudinal wave than the stereotypical transverse wave that is associated with audio, but they are a digital representation of an analog signal.

As can be seen in the figure above, the density of the high bits increases as the analog signal amplitude increases and, correspondingly, the digital signal stays at its low value for greater lengths of time when representing the lower end of the analog signal amplitude. This produces a signal that yields many of the benefits of a digital signal while still being directly correlated with the analog signal. Creating this PDM signal requires higher than usual sampling rates (rates above 3 MHz), as the digital pulses must occur many times more often than the oscillation of the analog signal they represent.

Due to the digital nature of the signal, PDM is much more resilient to electrically noisy environments than an analog signal and has an increased bit error tolerance when there is signal degradation. The high frequency signal does create distance limitations as increased capacitance on longer transmission lines may cause unwanted attenuation and an accompanying degradation in audio quality. These signals also require further processing by an external DSP or microcontroller with an appropriate codec to decimate, or downsample, the PDM signal to a lower sample rate by running it through a low-pass filter, thus making it usable for other devices. Its simple underlying concept means that PDM devices themselves only require two signals and tend to be less expensive, have smaller footprints, and use less power. However, these advantages may be offset by the additional circuitry required to process the signal coming from the PDM device.

Inter-IC Sound (I²S)

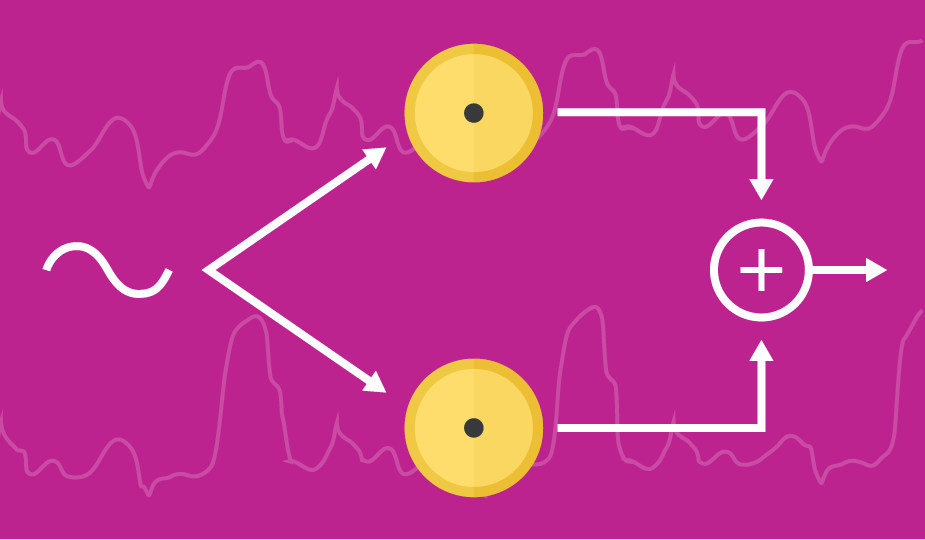

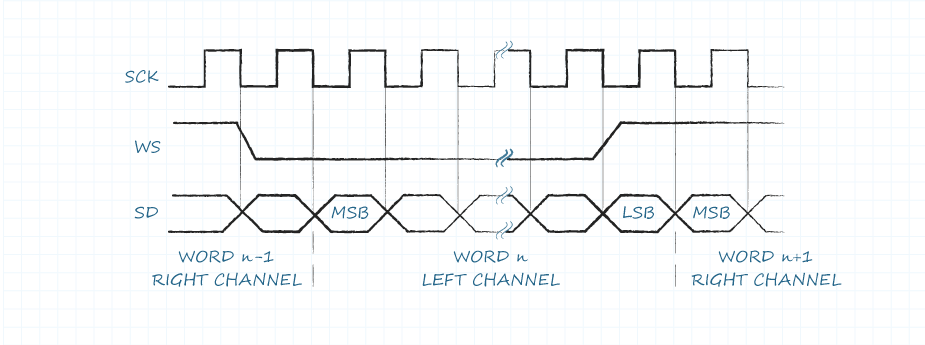

Originally emerging back in the mid-1980s, I²S is another popular interface option, though it is only recently becoming more integrated into smaller devices such as microphones. While the name invokes a relationship with I²C protocols, the similarity is purely coincidental. As with PDM, it is a dual-channel interface, but that is where the similarity ends.

The I2S protocol is a three-wire serial protocol with a clock, data, and “word select” line. In this case, “word select” indicates the channel, right or left, with which data currently being transmitted is associated. Unlike PDM, I2S is an entirely digital signal that does not need to be encoded or decoded. There is no universally required data transmission speed, however, the minimum speed is dependent on the data being transmitted and its precision. If the audio sample rate is the industry standard of 44.1 kHz with 8 bits of precision, then a mono channel will need a clock speed of at least 352.8 kHz. A stereo application would be double that at 705.6 kHz and any change in precision will also change the minimum transmission bandwidth.

Sample Frequency * Data Precision * Channel Number = Bandwidth

44,100 Hz * 8 bits * 2 channels = 705,600 Hz

While PDM mandates an external codec to bring its sample rate down, I²S utilizes an internal codec through its built-in filter. Therefore, the data rate of the audio signal is already at an acceptable level when it arrives at the DSP. This eliminates the need for additional components within the design for processing or conditioning the captured audio data. Based on this, I²S is likely to be the best path to follow in relation to price-sensitive products that are wholly self-contained and where energy efficient battery-powered operation is a prerequisite. This will be equally valid if the product they are being integrated into needs to be as compact as possible (wearables, handheld equipment, etc.).

Lastly, when comparing the resource requirements of PDM and I2S, it is important to note if there are already DSP capabilities integrated in the design. If so, the three signal lines and larger power consumption of an I2S device may be more resource intensive than a PDM device that can utilize the DSP capabilities already available on the board.

Interface Suitability for Different Applications

The better noise immunity and bit error tolerance that PDM offers can make this appealing for many applications where audio quality is a priority. In contrast, the ease of installation, reduced overall footprint, and lower component count that I2S enables will have merits in situations where the product size or its price tag prove to be among the main concerns. It should also be noted that the I2S interface will deliver better signal integrity over longer distances, so it can also be applicable for implementations where the microphone and the processing circuitry cannot be close to one another on the board. However, this cannot be taken to an extreme as I2S was not designed specifically for transmission over cables or other transmission devices, and many devices will not have proper impedance matching. Further research into the available parts, demands of the application, and data rates expected will be required on a case-by-case basis.

Conclusion

MEMS microphones are becoming commonplace in modern electronic design, and having an optimal interface is pivotal. There are numerous factors that will need to be considered when deciding which interface will be optimized for your particular application scenario. PDM can be the ideal choice in challenging application environments, thanks to its inherent resilience to noise. Conversely, employing I2S permits an input to connect directly to its accompanying DSP or other processor/controller devices without any additional complications. CUI Devices has an extensive portfolio of MEMS microphones that allow a diverse array of audio system requirements to be addressed. In addition to analog interface units, various digital interface microphones are also readily available.